Founded in Helsinki in 2019, Bloft Design Lab (Viima Mobility Oy) develops one of the largest 3D large format printers in Europe. They do plastic recycling by additive manufacturing. Originally the company was established to develop a smart mobility solution, hence the name Viima Mobility Oy. In 2019/20, they decided to pivot and focus only on their 3D printing technology. Initially Bloft worked with proven printing technology like plastic filament printing, but they soon realized that they were producing quite a lot of plastic waste that they couldn’t use them anymore once they were printed.

This insight led the team to develop a new printhead that was able to process plastic flakes produced by an industrial plastic shredding machine. They wanted to recycle their own failed prints. And then they realized the use any sort of thermoplastic would be revolutionary for 3D-printing. This is when the initial technology initiated idea turned into a greater story – they started to see plastic pollution not only as a problem, but a gigantic opportunity.

Bloft processes almost all thermoplastics and turns them into a desired product

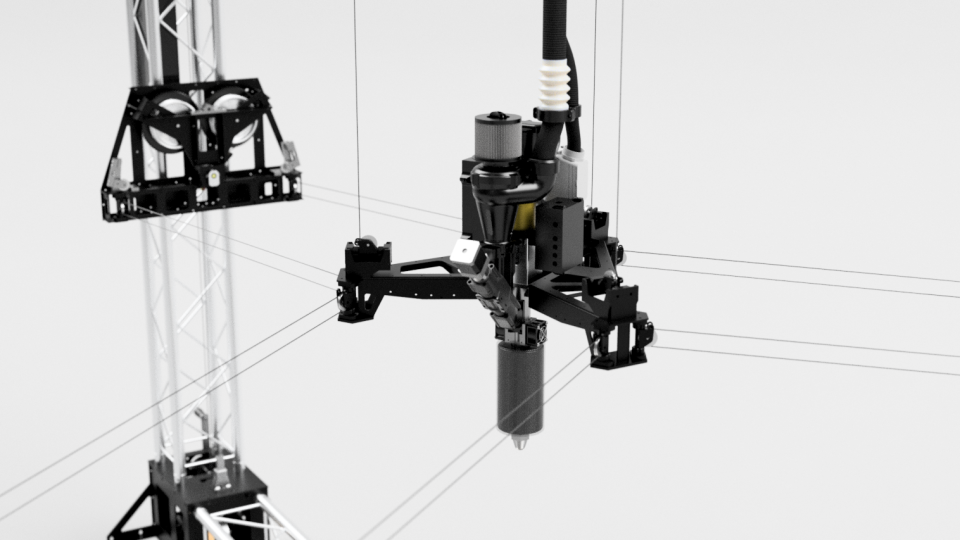

Bloft is the leading developer of Finland’s largest 3D printer which uses a new kind of technology for processing plastic. Common desktop 3D printers use plastic filament for printing which needs to be processed from raw plastic material – the pellets. Their print head surpasses this by using pellets. This saves energy and time. Furthermore, Bloft is able to use shredded plastic flakes, for instance made from failed prints, but also plastic waste like food packaging and other plastic products. This feature opens whole new possibilities for plastic recycling by making new products out of garbage.

Bloft basically wants the world to see the issue of plastic pollution not merely as a problem, but a great resource that should not be wasted and instead turned into profit and wealth. The reuse of plastic benefits not only the environment but also the climate. Every kilogram of plastic that we recycle has a 50% reduced CO2-footprint compared to virgin plastic and by keeping plastic in circulation instead of incinerating it, we can avoid the CO2 being released into the atmosphere.

Bloft examined in 2020 the material properties of plastic garbage collected on Helsinki’s shoreline. The collected material was found to be only 12% weaker than comparable virgin plastic and thus useful for many 3D printed applications. Considering plastic recycling in general, there is an established recycling system for food packaging only. And this affects only the consumer segment. Vast majority of plastic products, like buckets, toys, etc. end up in the incineration. This is where Bloft wants to step in by offering an alternative for profitable local level plastic recycling and would like to work together with the City of Helsinki to pilot their proposed plastic recycling solution and in the best case to make use of the plastic waste streams by the City’s departments and/or companies with ties to the City of Helsinki. In a true closed loop pilot the products they manufacture could be put in use for the general public or the needs of City departments.

The team hops on the train for Bloft’s journey

The core founding team consists of Atte Linna and Ville Ojala, two industrial designers, who teamed up during their studies and decided to found the company. Atte is a multitalent with a long history in building and operating 3D printers, but also has the ability to innovate and envision new products, services and business models. He acts as the CEO and lead designer. Ville is a talented prototyper and designer with a hang for mechanics. He acts as technical lead of the company.

During their journey, Roni-Pekka has joined the team while doing his Bachelor’s thesis in material testing for the company. Roni-Pekka is an enthusiastic 3D printer. In the team, he is responsible for the print production. Varpu joined the team as head of marketing and communication. She has been running the ROMU Company which piloted a smart plastic waste collection bin in 2021. She is an urban geography student. Omkar was introduced to the team by Urban Tech Helsinki. He is currently finalizing his Master’s degree in Robotics (KTH Royal Institute of Technology). Omkar will be responsible for the printer’s software and electronics, but thanks to his entrepreneurial mindset he will also work together with Atte in developing the business. He will join the team as the COO.

Urban Tech Helsinki generously provides resources that will contribute Bloft’s growth and development

After joining Urban Tech Helsinki program in the second round, Bloft Design Lab has perceived UTH as a great program for supporting them along their journey to the next level. Through the program, they gained access to great resources and the know-how in terms of pitching and funding while matching with new talents.

What Bloft is aiming for 2022 is to sell initial units for their printer’s beta program. The insights from the beta program will flow into the printer’s development which they are planning to finish in 2023. Commercial lauch is planned for 2023.

Currently they are looking for a talent with a commercial background to help them with go-to market planning and also for a greentech investor to back up their operations for the coming 12 to 18 months until the product launch.

To learn more about Bloft Design Lab, click here to visit their website.

This article was created in collaboration with Urban Tech Helsinki project.

Originally published on ArcticStartup : Original article