Syzygy Plasmonics is out to disrupt the $1 trillion chemical-manufacturing value chain.

The Houston-based startup, which bills itself as a “deep decarbonization company,” builds fully electric chemical reactors that are powered by light rather than traditional combustion.

That difference, CEO Trevor Best told us, is what will lead to disruption.

The big picture: “Chemical manufacturing is a foundation of modern human society,” Best pointed out. “With petroleum, natural gas and air, [companies] are able to create a wide variety of critical products,” from fuels and fertilizers to textiles and pharmaceuticals.

- “But today, it’s difficult to abate carbon emissions in chemical manufacturing,” he added. “That’s the problem Syzygy is working to solve.”

The backstory: In 2016, Best and Syzygy co-founder Dr. Suman Khatiwada “were looking for something disruptive” to invest in, Best said. “We reviewed lots of publications from major universities, and one day we happened to read about something happening at Rice University. This [idea] just would not die. We could not find a reason why it wouldn’t work, but no one else saw it.”

- After three decades of research, Rice researchers Naomi Halas and Peter Nordlander had developed a new kind of photocatalyst—a material that uses light to speed a chemical reaction—capable of “substantially lower[ing] the temperatures required for industrial-scale hydrogen production,” according to the university.

- “We quickly realized no one had ever made an industrial chemical reactor that could do that,” Best continued. He and Khatiwada contacted the researchers and eventually purchased the rights to the technology.

- Soon after, Syzygy was born.

Breaking records: In 2018, Syzygy successfully duplicated the Rice researchers’ experiment with a microreactor—but the result wasn’t as efficient at creating hydrogen as Best and Khatiwada wanted.

- They continued to scale up their testing, and by 2022, thanks to an advanced, large-cell reactor, the technology could produce hydrogen at 75% efficiency, surpassing the efficiency of traditional industrial chemical reactors.

- “We’re now on par with best-in-class electrolyzers” in terms of hydrogen production, Best said.

Affordable and emissions-free: One of the best things about Syzygy’s reactor? It produces no emissions, a characteristic the company believes will help it reach its goal of removing one gigaton of carbon dioxide emissions from the atmosphere by 2040.

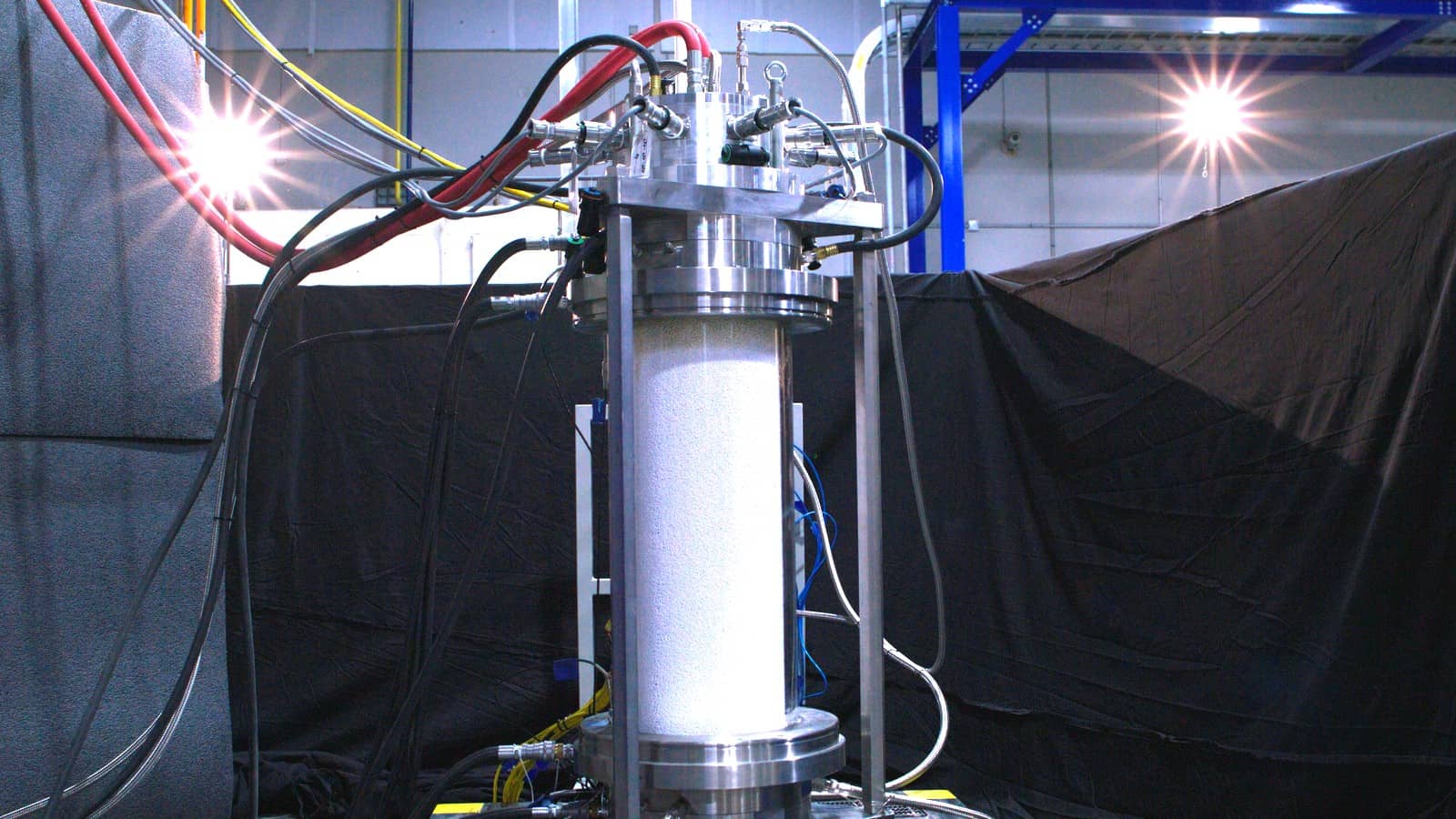

- Another selling point is that the reactor is made with low-cost, readily available materials. Earlier this year, Syzygy unveiled a six-foot-tall reactor—made of “low-cost steel and glass,” according to Best—at its industrial demonstration plant just outside Houston, where it runs every day.

- Capable of multiple types of chemical reactions, the reactor has drawn interest from multiple companies wanting to deploy the technology in their own operations. Syzygy already has signed several contracts.

Up next: The company plans to bring three separate reactions to market at once in the near future.

- In addition to being emissions-free, the three reactions cost less than their traditional-combustion-powered counterparts, by between 20% and 45%, according to Syzygy.

The last word: Syzygy doesn’t envision many limits in its future, said Best.

- “We see this thing going global,” Best said. “We’re talking to customers all over the world. … [In the beginning,] I thought I was crazy. This was a moonshot. But it has exceeded all our expectations.”

The post From Moonshot to Reality: Syzygy Plasmonics’ Emissions-Free Reactor first appeared on NAM.

Originally published on National Association of Manufacturers: Original article